Industrial Chemicals, Products, and Glues

Thin products include; dye, thin degreasers, liquid polish, thin solvents any other similar products. Thick products include glue, epoxies, caulking compounds, motor oils, and any other similar products.

Showing all 13 results

AccuWeight Filler

AccuWeight Fillers are net weight fillers designed for precise and accurate filling of liquid or semi-liquid products into drum or bucket containers ranging from 0.5 – 6 gallons (2-25L).

AccuWeight Filler

AccuWeight Fillers are net weight fillers designed for precise and accurate filling of liquid or semi-liquid products into drum or bucket containers ranging from 0.5 – 6 gallons (2-25L).

Pinch-25

The Pinch-25 is a timed flow volumetric liquid filling machine designed to fill water thin liquids, oils, and creams. All the contact parts can be easily cleaned and are autoclavable which makes the machine ideal for the medical, pharmaceutical, food, cosmetic, and specialty industries.

Pinch-25

The Pinch-25 is a timed flow volumetric liquid filling machine designed to fill water thin liquids, oils, and creams. All the contact parts can be easily cleaned and are autoclavable which makes the machine ideal for the medical, pharmaceutical, food, cosmetic, and specialty industries.

Pinch-50

The Pinch-50 is a versatile, timed flow volumetric filler designed to fill water thin liquids to oils and creams. All the contact parts can be easily cleaned and are autoclavable which makes the machine ideal for the medical, pharmaceutical, food, cosmetic, and specialty industries.

Pinch-50

The Pinch-50 is a versatile, timed flow volumetric filler designed to fill water thin liquids to oils and creams. All the contact parts can be easily cleaned and are autoclavable which makes the machine ideal for the medical, pharmaceutical, food, cosmetic, and specialty industries.

Screw Pump

The Accutek Screw Pump excels at handling thick Dense products such as grease, pastes, lotions, and heavy creams.

Screw Pump

The Accutek Screw Pump excels at handling thick Dense products such as grease, pastes, lotions, and heavy creams.

SAPOF

Accutek’s Semi-Automatic Pressure Overflow Fillers (SAPOF) are well suited filling machines for filling liquids with low to medium viscosities and are perfect for products that foam.

SAPOF

Accutek’s Semi-Automatic Pressure Overflow Fillers (SAPOF) are well suited filling machines for filling liquids with low to medium viscosities and are perfect for products that foam.

AccuVac Series

The Accuvac Series Filling Machines are easy to operate and are ideal for filling nail polish, perfumes, light oils, and other liquids in small amounts.

AccuVac Series

The Accuvac Series Filling Machines are easy to operate and are ideal for filling nail polish, perfumes, light oils, and other liquids in small amounts.

Auto-Pinch 25

The Auto-Pinch 25: A high-speed, versatile, automatic timed flow liquid filler reaching up to 100 containers per minute.

Auto-Pinch 25

The Auto-Pinch 25: A high-speed, versatile, automatic timed flow liquid filler reaching up to 100 containers per minute.

Auto Pinch 50

The Auto-Pinch 50 is an automatic timed flow volumetric filling machine capable of filling water thin liquids to light oils and creams at speeds of up to 100 containers per minute.

Auto Pinch 50

The Auto-Pinch 50 is an automatic timed flow volumetric filling machine capable of filling water thin liquids to light oils and creams at speeds of up to 100 containers per minute.

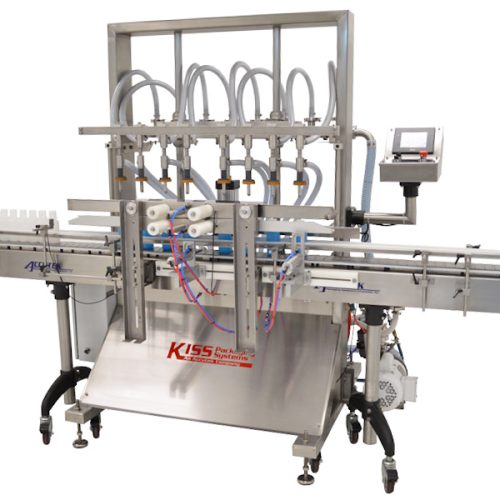

APOF Series – Automatic Pressure Overflow Filler

Automatic pressure overflow fillers are best suited for low to medium viscosity (200 cps) liquids. The precision engineered overflow nozzles guarantee that every container is filled to the same visual level.

APOF Series – Automatic Pressure Overflow Filler

Automatic pressure overflow fillers are best suited for low to medium viscosity (200 cps) liquids. The precision engineered overflow nozzles guarantee that every container is filled to the same visual level.

Auto Corrosive Filler- ACF

Accutek Corrosive Filling Machine is a specially designed timed flow volumetric filler for use in environments where caustic liquids and gasses cause accelerated deterioration to standard packaging machinery.

Auto Corrosive Filler- ACF

Accutek Corrosive Filling Machine is a specially designed timed flow volumetric filler for use in environments where caustic liquids and gasses cause accelerated deterioration to standard packaging machinery.

ROF-40

The bottle filling machine Rotary Overflow Filler-40, offers an extremely fast and accurate production for all free-flowing, non-carbonated liquids.

ROF-40

The bottle filling machine Rotary Overflow Filler-40, offers an extremely fast and accurate production for all free-flowing, non-carbonated liquids.

ROF-64

The Rotary Overflow Filling Machine is a fast and accurate production system that can be used for all free-flowing and non-carbonated liquids including foods, beverages, cosmetics, chemicals, and much more.

ROF-64

The Rotary Overflow Filling Machine is a fast and accurate production system that can be used for all free-flowing and non-carbonated liquids including foods, beverages, cosmetics, chemicals, and much more.

ROF-52

The Biner Ellison Rotary Overflow Filler (ROF Series) is a fast and accurate Filling System. This machine is a perfect choice for all free-flowing, non-carbonated liquid products.

ROF-52

The Biner Ellison Rotary Overflow Filler (ROF Series) is a fast and accurate Filling System. This machine is a perfect choice for all free-flowing, non-carbonated liquid products.

Timed filling machines use either a pinch bar that cuts off and releases product to all nozzles at the same time. In a ball valve system, there is a valve for each nozzle to start and stop product flow into the container. The products listed above use one or the other of these techniques to accomplish accurate and consistent fill levels throughout a production run. The pinch series machines have adjustable flow rates at each nozzle to ensure that individual containers are filled to the proper level.

Accutek also has timed flow gravity fillers where each nozzle has its own timer for super precise fill level control. Timed flow gravity fillers can be ordered with corrosion resistant components.

Fill to level or overflow filler nozzle configuration sets a consistent fill level across many containers. The timed fill and overflow fillers are best with thinner products. For thicker products the following filler technology works better.

Using check valves, piston fillers pull product into a cylinder with a piston and then push the product out through the nozzle. The fill volume is determined by the stroke length. The cylinder diameter you choose balances between fill time and consistency. Piston fillers can be ordered with pneumatic or electric piston drivers.

Positive displacement (PD) fillers count pump shaft rotations to determine the fill level. PD fillers can handle small non-abrasive particles but are best with free flowing oils and creams. Accutek sells a manual single container PD filler and a high end automatic machine that can fill up to twelve containers at a time.

All but the basic entry level fillers have a color touch screen that is linked to a PLC (Programmable Logic Controller) that operates the machine. The machine operating program gives the operator the ability to make fine adjustments to the machine as needed during a shift. The logic continuously monitors the machine for correct operation along with built in safety checks.

Accutek fillers range from entry level fill machines to automated machines that can fill up to twelve containers per cycle. At the high end Accutek has a selection of rotary fillers that fill containers to level in a continuous process achieving maximum throughput.