Showing all 15 results

AccuWrapper

Designed to work tirelessly under tough industrial conditions, the Accutek e-cigarette equipment AccuWrapper gives customers a reliable powered pallet wrapping assistant that will increase efficiency and cut labor and film costs.

AccuWrapper

Designed to work tirelessly under tough industrial conditions, the Accutek e-cigarette equipment AccuWrapper gives customers a reliable powered pallet wrapping assistant that will increase efficiency and cut labor and film costs.

Mini-Pinch

The Mini-Pinch is a filling machine best suited for filling aqueous solutions, thin and light oils. The Mini-Pinch is a six-head, timed flow volumetric filler that has a fill rate up to six ounces per second. An experienced operator can fill up to two thousand five hundred bottles per hour; it is also highly accurate even when filling 10 ml. Bottles.

Mini-Pinch

The Mini-Pinch is a filling machine best suited for filling aqueous solutions, thin and light oils. The Mini-Pinch is a six-head, timed flow volumetric filler that has a fill rate up to six ounces per second. An experienced operator can fill up to two thousand five hundred bottles per hour; it is also highly accurate even when filling 10 ml. Bottles.

Auto-Indexing Mini-Pinch

The Indexing Mini Pinch is a timed flow filling machine best suited for liquid filling solutions, thin and light oils. The Automatic Indexing Mini Pinch is a six-head, timed flow volumetric filler that has a fill rate of up to six ounces per second.

Auto-Indexing Mini-Pinch

The Indexing Mini Pinch is a timed flow filling machine best suited for liquid filling solutions, thin and light oils. The Automatic Indexing Mini Pinch is a six-head, timed flow volumetric filler that has a fill rate of up to six ounces per second.

SVF Series

Accutek’s Semi-Automatic Volumetric Fillers (SVF) are piston fillers that accurately deliver a measured volume of product to each container. The accuracy of these machines ensures bottom line savings by reducing the amount of product that is used as overfill.

SVF Series

Accutek’s Semi-Automatic Volumetric Fillers (SVF) are piston fillers that accurately deliver a measured volume of product to each container. The accuracy of these machines ensures bottom line savings by reducing the amount of product that is used as overfill.

AccuVac Series

The Accuvac Series Filling Machines are easy to operate and are ideal for filling nail polish, perfumes, light oils, and other liquids in small amounts.

AccuVac Series

The Accuvac Series Filling Machines are easy to operate and are ideal for filling nail polish, perfumes, light oils, and other liquids in small amounts.

Auto Mini Pinch

The Auto Mini Pinch is an automatic timed flow volumetric filling machine capable of filling water thin liquids to light oils and creams at speeds of up to 100 containers per minute. Minimal contact parts (hose only) make the machine ideal for sanitary filling of food, pharmaceutical, cosmetic, and specialty products.

Auto Mini Pinch

The Auto Mini Pinch is an automatic timed flow volumetric filling machine capable of filling water thin liquids to light oils and creams at speeds of up to 100 containers per minute. Minimal contact parts (hose only) make the machine ideal for sanitary filling of food, pharmaceutical, cosmetic, and specialty products.

Auto AccuVac Series

Customers looking for a cost-effective filler to produce visually appealing and consistent fill levels —no matter their container’s shape or volume—can’t go wrong with an Auto AccuVac series filling machine.

Auto AccuVac Series

Customers looking for a cost-effective filler to produce visually appealing and consistent fill levels —no matter their container’s shape or volume—can’t go wrong with an Auto AccuVac series filling machine.

ROF-52

The Biner Ellison Rotary Overflow Filler (ROF Series) is a fast and accurate Filling System. This machine is a perfect choice for all free-flowing, non-carbonated liquid products.

ROF-52

The Biner Ellison Rotary Overflow Filler (ROF Series) is a fast and accurate Filling System. This machine is a perfect choice for all free-flowing, non-carbonated liquid products.

AccuCapper HDEX

AccuCapper™ HDEX is a “heavy duty”, portable, handheld cap tightener capable of tightening or removing screw and lug type closures.

AccuCapper HDEX

AccuCapper™ HDEX is a “heavy duty”, portable, handheld cap tightener capable of tightening or removing screw and lug type closures.

AccuCapper BT

AccuCapper™ BT Semi-Auto Bench Top Chuck Capping Machine automatically tightens screw and lug type closures that have been placed on containers. The AccuCapper™ BT pneumatic clutch ensures an accurate and specific torque each and every time.

AccuCapper BT

AccuCapper™ BT Semi-Auto Bench Top Chuck Capping Machine automatically tightens screw and lug type closures that have been placed on containers. The AccuCapper™ BT pneumatic clutch ensures an accurate and specific torque each and every time.

Labelette SPS-104

Labelette’s (Semi-Automatic Pressure Sensitive) SPS-104 is an economical and efficient labeling machine for round containers. The unit is manufactured from Stainless Steel and anodized aluminum creating a durable but portable machine.

Labelette SPS-104

Labelette’s (Semi-Automatic Pressure Sensitive) SPS-104 is an economical and efficient labeling machine for round containers. The unit is manufactured from Stainless Steel and anodized aluminum creating a durable but portable machine.

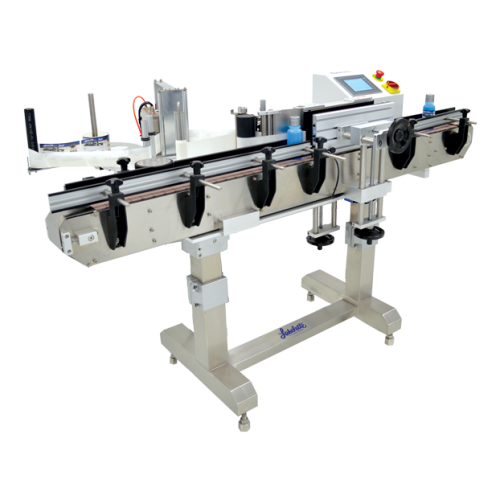

APS 106

The labeling machine APS-106 is economical, self-contained and easy to operate. This automatic labeling system comes equipped with a 6 ft. variable speed conveyor.

APS 106

The labeling machine APS-106 is economical, self-contained and easy to operate. This automatic labeling system comes equipped with a 6 ft. variable speed conveyor.

AccuSleever

The AccuSleever places heat shrinkable tamper evident bands on containers. Containers move through the machine on a conveyor at rates up to 65 containers per minute.

AccuSleever

The AccuSleever places heat shrinkable tamper evident bands on containers. Containers move through the machine on a conveyor at rates up to 65 containers per minute.

G7 Shrink Tunnel

Phase Fire G7 is the perfect tunnel for tamper evident banding. It implements a tapered heating process that shrinks plastic safety seals evenly, giving your bottle a professional look.

G7 Shrink Tunnel

Phase Fire G7 is the perfect tunnel for tamper evident banding. It implements a tapered heating process that shrinks plastic safety seals evenly, giving your bottle a professional look.

G9 Tunnel

The G9 high temperature recirculating shrink tunnel oven is primarily used for tamper evident bands, neck-bands and capsule sealing applications.

G9 Tunnel

The G9 high temperature recirculating shrink tunnel oven is primarily used for tamper evident bands, neck-bands and capsule sealing applications.

Expand your business capabilities with Accutek piston and volumetric filling machine. By accommodating a wide range of e-liquid products, we offer specialized equipment at a reasonable price for the vapor, electric cigarette, and e-liquid industries.

Our e-cig filling machines use a piston and ball valve to fill cartridges with the measured amount of e-liquid. The process involves flow gravity fillers and timers for accurate fill levels.

E-liquid filling machines by Accutek maintain accuracy to deliver measured volumes of liquid in each container. Apart from automating the filling process, we aim to enhance bottom-line savings for our customers with a specially designed machine.

Using fully and semi-automatic configurations, these electric cigarette filling systems address human errors and product wastage.

Applications for Our e-Cig Filling Machine

Electric cigarette filling requires extreme precision and control over operations. Accutek offers a range of fillers to ensure both in every production line. Whether you choose our rotary overflow fillers or mini-dose fillers, our innovative technology provides consistent fill levels with variable speed controls and optional specialty pumps.

The systems work for filling and packaging products like electric cigarettes, essential oils, vaping fluids, any flavored e-liquid, etc. You may shop for our equipment to fill semi-viscous and thin liquids.

Each machine has a bottling capacity of 0.1 ml to 475 ml for a viscosity range of 1 cP to 1000 cP. Since high-quality vaporizer pens and cigarettes are essential for enhanced user experiences, attract more customers with our piston-based electric cigarette filling machine for precise fill consistency and volumes.

For drip-less operations and a minimal hold-up volume, choose our high-end filling machines available with excellent control features, programmable speed controls, and dispensing precision for filling e-cigarettes.

Product Features and Benefits

Our timed filling machines offer consistent and precise control over every production run, whether you need a filler for aqueous solutions or thin liquids.

Sturdy Construction

Each automatic or semi-automatic filling machine comes with stainless steel filling heads. The Mini Pinch series ensure individual flow control in each filling head. We use food-grade tubing and stainless steel nozzles for sanitation throughout the electric cigarette filling process.

All wetted parts have sloping and curved surfaces for easy cleaning. The compact design makes the machine portable and easy to store anywhere in your facility. It is also easy to dismantle for cleaning.

Automated Control Features

Each e-cigarette filling machine has an integrated touch screen feature with a jog memory, user-friendly menus, and pre-programmed software. You can program table speed, fill volume, and pump speed during the operations.

Ask for additional features like custom nozzles, all-pneumatic upgrade, stainless steel sanitary hoppers, custom bottle trays, guides, or precision heated tanks with selected models for filling electric cigarettes. The custom features come with an extra price.

The advanced Accu-doser uses medical-grade syringes for filling micro or mini doses. Automatic head fillers and Servo-driven peristaltic pumps for non-contact filling make this injector machine ideal for sterile applications.

Customization and Optional Upgrades

If product specifications don’t match your production needs, shop for our customizable electric cigarette filling machine. We manufacture mini-pinch fillers for high-VG e-juices. The custom-built design facilitates filling sizes over 30 ml at a higher speed due to its four-part manifold and nozzle size.

Our high-tech injector machine offers optional features like a sealed membrane tank, thick viscosity flow components, refill tanks, fill trays, harsh chemical pumps, and glass syringe pumps to inject fluids into candies and gummies. You can fill dosage sizes from 0.1 ml to 200 ml with our filling machine.

Our Range of Electric Cigarette Filling Machines

Shop with Accutek and expedite your e-liquid packaging solutions with an Accutek e-cig filling machine. Besides fillers, our range also includes labelers, cappers, and shrink tunnels for tamper-evident banding and automated labeling. The range of e-liquid filling systems includes:

Mini-Pinch machines come with a six-head volumetric filler for light and thin oils for e-cigarettes. The machine ensures a higher fill rate of up to six ounces per second to fill around 2500 bottles in an hour. With pinch valve and injector mode, the machine is autoclavable, and pneumatic configurations ensure better efficiency.

Our automatic indexing mini-pinch series reduces the workload using a programmable logic controller for handling machine operations. Fill six bottles in a row with an integrated wand. The PLC also monitors the operations using individual flow control adjusters.

When you need cost-effective, quality solutions for filling liquids with low viscosity, shop for Accutek semi-automatic volumetric fillers. These flexible machines facilitate filling operations for various liquids ranging in viscosity and thickness. With butterfly valve updates and optional hoppers, this machine is perfect for e-cigarettes and vaping products.

The pneumatic operations of the Accuvac series are ideal for filling any flammable e-liquid in small cartridges or containers. With adjustable fill levels, portable design, and precision, this machine assures guaranteed fill levels irrespective of liquid viscosity.

Visit our product page for a price quote or contact us today to know more about our electric cigarette filling solutions.