The bottling challenge is putting the correct amount of product into a bottle or container as quickly as possible. Accutek entered the packaging industry thirty years ago with its first product, a bottling machine. Today, Accutek Packaging Equipment Companies, Inc., is one of the largest packagings and bottling machine manufacturers in the United States. A leading developer and manufacturer of complete packaging solutions where bottling systems are an integral component. Accutek Packaging Equipment Companies offer a wide variety of bottling machines, as well as capping, and labeling machines. We pride ourselves on being able to support startup companies that need economical semi-automatic bottle fillers. We also have the depth of experience needed to service larger companies with world-class technology, providing automatic packaging lines at competitive prices.

Showing all 27 results

AccuWeight Filler

AccuWeight Fillers are net weight fillers designed for precise and accurate filling of liquid or semi-liquid products into drum or bucket containers ranging from 0.5 – 6 gallons (2-25L).

AccuWeight Filler

AccuWeight Fillers are net weight fillers designed for precise and accurate filling of liquid or semi-liquid products into drum or bucket containers ranging from 0.5 – 6 gallons (2-25L).

Mini-Pinch

The Mini-Pinch is a filling machine best suited for filling aqueous solutions, thin and light oils. The Mini-Pinch is a six-head, timed flow volumetric filler that has a fill rate up to six ounces per second. An experienced operator can fill up to two thousand five hundred bottles per hour; it is also highly accurate even when filling 10 ml. Bottles.

Mini-Pinch

The Mini-Pinch is a filling machine best suited for filling aqueous solutions, thin and light oils. The Mini-Pinch is a six-head, timed flow volumetric filler that has a fill rate up to six ounces per second. An experienced operator can fill up to two thousand five hundred bottles per hour; it is also highly accurate even when filling 10 ml. Bottles.

Auto-Indexing Mini-Pinch

The Indexing Mini Pinch is a timed flow filling machine best suited for liquid filling solutions, thin and light oils. The Automatic Indexing Mini Pinch is a six-head, timed flow volumetric filler that has a fill rate of up to six ounces per second.

Auto-Indexing Mini-Pinch

The Indexing Mini Pinch is a timed flow filling machine best suited for liquid filling solutions, thin and light oils. The Automatic Indexing Mini Pinch is a six-head, timed flow volumetric filler that has a fill rate of up to six ounces per second.

Pinch-25

The Pinch-25 is a timed flow volumetric liquid filling machine designed to fill water thin liquids, oils, and creams. All the contact parts can be easily cleaned and are autoclavable which makes the machine ideal for the medical, pharmaceutical, food, cosmetic, and specialty industries.

Pinch-25

The Pinch-25 is a timed flow volumetric liquid filling machine designed to fill water thin liquids, oils, and creams. All the contact parts can be easily cleaned and are autoclavable which makes the machine ideal for the medical, pharmaceutical, food, cosmetic, and specialty industries.

Pinch-50

The Pinch-50 is a versatile, timed flow volumetric filler designed to fill water thin liquids to oils and creams. All the contact parts can be easily cleaned and are autoclavable which makes the machine ideal for the medical, pharmaceutical, food, cosmetic, and specialty industries.

Pinch-50

The Pinch-50 is a versatile, timed flow volumetric filler designed to fill water thin liquids to oils and creams. All the contact parts can be easily cleaned and are autoclavable which makes the machine ideal for the medical, pharmaceutical, food, cosmetic, and specialty industries.

SVF Series

Accutek’s Semi-Automatic Volumetric Fillers (SVF) are piston fillers that accurately deliver a measured volume of product to each container. The accuracy of these machines ensures bottom line savings by reducing the amount of product that is used as overfill.

SVF Series

Accutek’s Semi-Automatic Volumetric Fillers (SVF) are piston fillers that accurately deliver a measured volume of product to each container. The accuracy of these machines ensures bottom line savings by reducing the amount of product that is used as overfill.

SAPD-1

The SAPD-1 is a single head Semi-Automatic Positive Displacement Pump filling system designed to handle all types of rigid plastic, metal and glass containers.

SAPD-1

The SAPD-1 is a single head Semi-Automatic Positive Displacement Pump filling system designed to handle all types of rigid plastic, metal and glass containers.

SAPD-2 Positive Displacement Filling Machine

The Semi-Automatic 2 Head Positive Displacement Filling Machines (SAPD-2) utilize a Positive Displacement Pump Head for each fill head.

SAPD-2 Positive Displacement Filling Machine

The Semi-Automatic 2 Head Positive Displacement Filling Machines (SAPD-2) utilize a Positive Displacement Pump Head for each fill head.

SAPOF

Accutek’s Semi-Automatic Pressure Overflow Fillers (SAPOF) are well suited filling machines for filling liquids with low to medium viscosities and are perfect for products that foam.

SAPOF

Accutek’s Semi-Automatic Pressure Overflow Fillers (SAPOF) are well suited filling machines for filling liquids with low to medium viscosities and are perfect for products that foam.

Auto Mini Pinch

The Auto Mini Pinch is an automatic timed flow volumetric filling machine capable of filling water thin liquids to light oils and creams at speeds of up to 100 containers per minute. Minimal contact parts (hose only) make the machine ideal for sanitary filling of food, pharmaceutical, cosmetic, and specialty products.

Auto Mini Pinch

The Auto Mini Pinch is an automatic timed flow volumetric filling machine capable of filling water thin liquids to light oils and creams at speeds of up to 100 containers per minute. Minimal contact parts (hose only) make the machine ideal for sanitary filling of food, pharmaceutical, cosmetic, and specialty products.

Auto-Pinch 25

The Auto-Pinch 25: A high-speed, versatile, automatic timed flow liquid filler reaching up to 100 containers per minute.

Auto-Pinch 25

The Auto-Pinch 25: A high-speed, versatile, automatic timed flow liquid filler reaching up to 100 containers per minute.

Auto Pinch 50

The Auto-Pinch 50 is an automatic timed flow volumetric filling machine capable of filling water thin liquids to light oils and creams at speeds of up to 100 containers per minute.

Auto Pinch 50

The Auto-Pinch 50 is an automatic timed flow volumetric filling machine capable of filling water thin liquids to light oils and creams at speeds of up to 100 containers per minute.

AVF Series – Automatic Piston Filling Machine

Accutek’s Automatic Volumetric Piston Filling Machines (AVF) are heavy duty filling powerhouses. They deliver precision dose filling, have flexible filling options, and offer multi work shift reliability.

AVF Series – Automatic Piston Filling Machine

Accutek’s Automatic Volumetric Piston Filling Machines (AVF) are heavy duty filling powerhouses. They deliver precision dose filling, have flexible filling options, and offer multi work shift reliability.

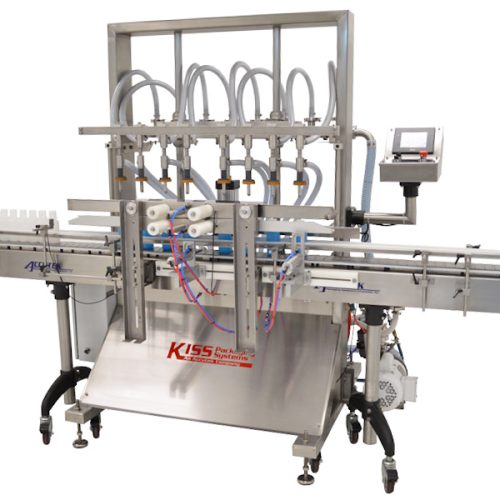

APD Series

KISS Automatic Positive Displacement (APD) Fillers have been specifically designed and built to handle both the thinnest and most viscous liquid products on the market.

APD Series

KISS Automatic Positive Displacement (APD) Fillers have been specifically designed and built to handle both the thinnest and most viscous liquid products on the market.

APOF Series – Automatic Pressure Overflow Filler

Automatic pressure overflow fillers are best suited for low to medium viscosity (200 cps) liquids. The precision engineered overflow nozzles guarantee that every container is filled to the same visual level.

APOF Series – Automatic Pressure Overflow Filler

Automatic pressure overflow fillers are best suited for low to medium viscosity (200 cps) liquids. The precision engineered overflow nozzles guarantee that every container is filled to the same visual level.

Auto AccuVac Series

Customers looking for a cost-effective filler to produce visually appealing and consistent fill levels —no matter their container’s shape or volume—can’t go wrong with an Auto AccuVac series filling machine.

Auto AccuVac Series

Customers looking for a cost-effective filler to produce visually appealing and consistent fill levels —no matter their container’s shape or volume—can’t go wrong with an Auto AccuVac series filling machine.

Auto Corrosive Filler- ACF

Accutek Corrosive Filling Machine is a specially designed timed flow volumetric filler for use in environments where caustic liquids and gasses cause accelerated deterioration to standard packaging machinery.

Auto Corrosive Filler- ACF

Accutek Corrosive Filling Machine is a specially designed timed flow volumetric filler for use in environments where caustic liquids and gasses cause accelerated deterioration to standard packaging machinery.

ROF-40

The bottle filling machine Rotary Overflow Filler-40, offers an extremely fast and accurate production for all free-flowing, non-carbonated liquids.

ROF-40

The bottle filling machine Rotary Overflow Filler-40, offers an extremely fast and accurate production for all free-flowing, non-carbonated liquids.

ROF-64

The Rotary Overflow Filling Machine is a fast and accurate production system that can be used for all free-flowing and non-carbonated liquids including foods, beverages, cosmetics, chemicals, and much more.

ROF-64

The Rotary Overflow Filling Machine is a fast and accurate production system that can be used for all free-flowing and non-carbonated liquids including foods, beverages, cosmetics, chemicals, and much more.

ROF-52

The Biner Ellison Rotary Overflow Filler (ROF Series) is a fast and accurate Filling System. This machine is a perfect choice for all free-flowing, non-carbonated liquid products.

ROF-52

The Biner Ellison Rotary Overflow Filler (ROF Series) is a fast and accurate Filling System. This machine is a perfect choice for all free-flowing, non-carbonated liquid products.

RVF-52

Elevate design standards with the RVF-52, filling machine. Achieve higher speed, safety, and productivity while maintaining efficiency and cost-effectiveness.

RVF-52

Elevate design standards with the RVF-52, filling machine. Achieve higher speed, safety, and productivity while maintaining efficiency and cost-effectiveness.

RPD-40 Positive Displacement Fillers

The RPD-40 is a member of the Positive Displacement Fillers family. These Positive Displacement Fillers utilize an individual PD Pump Head for each fill head.

RPD-40 Positive Displacement Fillers

The RPD-40 is a member of the Positive Displacement Fillers family. These Positive Displacement Fillers utilize an individual PD Pump Head for each fill head.

RPD-52

Similar to RPD-40, the Rotary Positive Displacement filler utilizes individual PD Pump Heads for each fill head and is a commercial bottle filler used for rapid bottle filling.

RPD-52

Similar to RPD-40, the Rotary Positive Displacement filler utilizes individual PD Pump Heads for each fill head and is a commercial bottle filler used for rapid bottle filling.

ROPP Capper

AccuCapper ROPP Capper is a Roll Over Pilfer Proof capper designed to thread and seal aluminum caps onto rigid containers.

ROPP Capper

AccuCapper ROPP Capper is a Roll Over Pilfer Proof capper designed to thread and seal aluminum caps onto rigid containers.

SSC-6

Accutek’s Semi-Automatic Spindle Capper (SSC-6) a capping machine uses the latest technology to accurately torque most cap types onto a wide range of bottles.

SSC-6

Accutek’s Semi-Automatic Spindle Capper (SSC-6) a capping machine uses the latest technology to accurately torque most cap types onto a wide range of bottles.

106 Fabric Belt Labeler

The labeling machine APS 106 Fabric Belt Labeler is a revolutionary automatic pressure sensitive labeler designed for efficient label application onto containers.

106 Fabric Belt Labeler

The labeling machine APS 106 Fabric Belt Labeler is a revolutionary automatic pressure sensitive labeler designed for efficient label application onto containers.

Custom Options for Bottling Machines

Each customer has unique product and container combinations. We routinely customize our bottling systems to accommodate specialized glass or plastic containers and product combinations. We are also adept at integrating our products into existing packaging lines.

Finding the Best Bottling Machines for Your Needs

Here are factors that should be considered when searching for the correct bottling machinery for your product line. Bottling machinery selection is driven by your product characteristics, viscosity being the primary metric. Peanut butter is put in a bottle by a liquid filling machine, as is acetone. Peanut butter and acetone are both liquids but at opposite ends of the viscosity range. The bottling system needed to move peanut butter into a bottle is very different than the bottling system used for acetone.

What type of bottling system is best suited for your product viscosity and other characteristics? There are four different bottling technologies, piston, timed flow, metered flow, and overflow. Peanut butter is best handled by a piston filler that keeps the product warm and therefore at a lower viscosity, all driven by a strong pneumatic cylinder. Acetone, on the other hand, can be gravity fed into an overflow filler.

Volumetric Bottling Machines

Timed Flow Bottling Machines

Metered Flow Bottling Machines

Overflow Bottling Machines

Bottle Selection

Selecting a bottle is the next step as you design your liquid filling system. A simple straight-sided round bottle can be handled by off the shelf components. If you choose a novelty bottle, you will increase the time to design, manufacture, and test your plastic bottling machine.

As a business starts and expands, the needed production rates from their bottling system increases. A startup company’s first machine will typically be a simple bottling machine that may fill a single plastic or glass bottle at a time with an operator handling the containers before and after filling. Increasing the number of nozzles on a bottling system increases production rates and thus the type of bottling machine from semi-automatic to fully automatic. Bottling systems that process glass or plastic containers have as many as twelve nozzles filling at the same time are not uncommon. In these filling systems, a conveyor belt moves the containers under the nozzles, pauses while the liquid fills the bottles, and then moves the filled containers out.

Accutek Sales engineers have the training and experience to assist you with selecting the optimum bottling machinery for your production rates, product, and container combination.