Positive displacement (PD) volumetric filling systems can fill a wide variety of products ranging from thin alcohol to thick caulking compounds. PD fillers are used to fill conventional containers, as well as thinner walled containers that can be distorted by vacuum or high pressure.

The advantages of (PD) volumetric fillers are accuracy, flexibility, and reliability. Delivering an accurately metered volume of product to each container reduces cost by using less product than other filling techniques. Volumetric filling systems can be cleaned using automated flushing techniques.

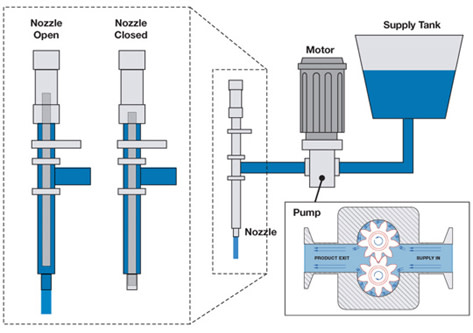

Positive displacement fillers deliver a measured amount of product to the container by utilizing a servo controlled pump head. A programmable logic controller (PLC) counts the number of pump shaft rotations. The number of shaft rotations determines the amount of product pumped.

Positive displacement (PD) fillers utilize a pump for each fill head. There are several pump technologies that work well with positive displacement fillers. Your Accutek Sales Representative can assist you with choosing the correct pump type.

Pump Head Selection

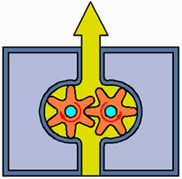

Gear Pump

A stainless steel gear ships standard with APD series fillers. The pump housing is stainless steel and the driven gear is also stainless steel. The bushings inside the pump head that maintain the position of the gears are glass impregnated Teflon.

These pumps are designed to handle abrasive free, viscous liquids. These pumps use two revolving gears that mesh together to pick up fluid from the intake and force it out under pressure through the discharge.

They generate high flow rates at moderate pressure working on the positive displacement principle.

Gear pumps are best suited for moving viscous products with no particulates. If the product is heated brass gears can be used.

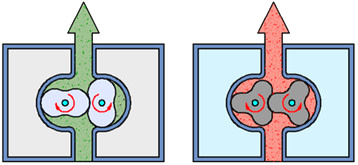

Lobe Pump

This type of gear pump has two or three lobes on each shaft. The lobes nearly touch each other in the center, forming a tight seal. They also nearly touch the casing. As the lobes rotate they move fluid around the outer edge of the pump to the discharge port.

The output of this type of pump pulsates more than a gear pump because there are fewer teeth.

This pump is well suited to move semi-liquid products with large particulates such as salsa, tomato pastes, and whole fruit. This pump is easy to sanitize when the contact parts are stainless steel.

This pump head type is available as an upgrade if sanitation is a concern or for food products that contain particulates. These pumps are not recommended for pumping abrasive products.

Flexible Impeller Pumps

Flexible vanes create a low pressure zone as the vanes rotate past the pump inlet drawing liquid into the pump.

As the flexible vanes rotate, the liquid is moved through the pump from the inlet to outlet port.

.

Flexible impeller pumps can be used for food grade or sanitary processes depending on elastomers and pump housing used. These pumps can pump semi-abrasive and viscous liquids, hard and soft solids, chemicals, slurries, and shear sensitive products. Flexible impeller pumps are used when output pressure needed is no more than 20 psi. These pumps can be used with temperatures up to impeller and housing rating.

Flexible impeller pumps cannot be run dry or used to pump products that are sticky. Flexible impeller pumps are best suited to products with natural lubricity and low abrasiveness.

Specifying a nozzle is as crucial as pump selection.

Nozzle Selection

Different types of products require different nozzle designs. The nozzle used to fill an ampule with 10 ml of thin fluid would not be appropriate for filling a five-gallon can with paint. There are numerous sizes and shapes of nozzles available between these two extremes.

The diameter of the nozzle should be selected to provide a smooth flow. If it is too small, the velocity of the material will be too high as it enters the container and there may be splashing and foaming. If the nozzle is too large, the product may drip at the end of each fill.

A bubble forms at the tip of the nozzle after each fill when the nozzle diameter matches the surface tension of the product. This keeps any material left in the nozzle from dripping out. There may be a few drips at the end of each fill if the nozzle diameter is too large. This can make it necessary to either run the process slower so that all the drips are caught in the container or require extra cleaning of the containers and the filler.

Some nozzles direct the flow downward in a solid stream; others break it up into a spray, or direct it to the side of the container so that it will run down the sides. A screen can be mounted inside a nozzle to reduce foaming. The best way to select a nozzle for a specific product is laboratory testing with a number of different types of nozzles. Using the wrong nozzle can cause slow operation, loss of product, uneven fills, and a messy machine.

Positive off nozzles

Positive off nozzles have a moving nozzle tip that retracts or extends to seal the nozzle between fills.

Diving nozzle kit

The diving nozzle kit is an upgrade that is used for products that cavitate, are foamy, or “pillow”. The nozzles lower into the container and fill from the bottom up producing a smooth fill as the nozzle pulls up during the fill cycle.

PD fillers can be ordered with drip trays and neck grabbers to better manage the containers during the fill process. Product tanks and nozzles can be equipped with heaters for product that is too thick to flow at room temperatures.

|

Food & Beverages |

Cosmetic & Personal Care |

Chemical |

Pharmaceutical |

Other |

|

Water |

Perfumes |

Window Cleaners |

Cough Medicine |

Insect repellent |

|

Fruit Juices |

Essential Oils |

Laundry Detergent |

Urine |

|

|

Vegetable Oil |

Nail Polish |

Motor Oil |

Alcohol |

|

|

Tea |

Nail Polish Remover |

Ink |

Iodine |

|

|

Fruit Extracts |

Air Freshener |

Stain Removers |

Saline Solution |

|

|

Vitamin Drinks |

Liquid Soap |

Carpet Cleaners |

||

|

Syrups |

Sun Tan Lotion |

Paint |

||

|

Food Coloring |

Shampoo |

Degreasers |

||

|

Tomato Juice |

Hair Conditioner |

Fuel Additives |

||

|

Salad Dressing |

Hand & Body Lotion |

Engine Coolant |

||

|

Tooth Paste |

Mouth Wash |

Wood Stain |

||

|

Peanut Butter |

Bubble Bath |

Wood Varnish |

||

|

Milk |

Lip Balm |

Candles |

||

|

Honey |

Hair Styling Gels |

Wax |

||

|

Mayonnasie |

Facial Mud |

Tire Sealants |

||

|

Sour Cream |

Mascara |

Grease |

||

|

Cheese |

Eye Liner |

Glue |

||

|

Fruit Toppings |

Makeup Remover |

Silicone |

||

|

Jellies |

Facial Creams |

Aircraft Paint |

||

|

Jams |

||||

|

Molasses |

||||

|

Yogurt |

||||

|

Salsa |

||||

|

Soups |

||||

|

Chili |