You have done your research and have a killer product, an attractive container with a clever dispenser. You have solid funding without taking a second mortgage on the house. The only problem remaining is setting up your production line.

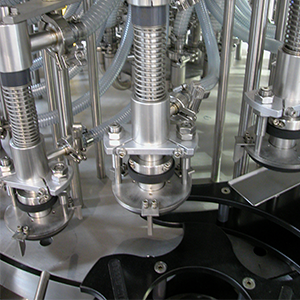

The center piece of the line is going to be the filling machine. The filler is the stainless steel marvel that takes your wonderful product and precisely fills containers at the highest speed possible.

This is where reality sets in. A filling machine putting a watery, low viscosity, product into a 2-ounce bottle can go very fast. Loading a tub with 16 ounces of chunky salsa will take quite a bit longer and requires a more complex filler. The four filler categories are as follow:

Timed flow filler

Product flows through a nozzle for a controlled time. A product flow control valve is needed to equalize the dose delivered by each nozzle. Once set up, this type of filler delivers the same volume of product each cycle. A timed flow filling machine can have up to twelve nozzles. These type fillers are compatible with most free flowing products that are particulate free.

Overflow filler

Overflow filler nozzles are coaxial. The inner tube delivers product to the container and the outer tube provides a product overflow path once the container is full. The insertion depth of the nozzle sets the fill level. On the store shelf, every container will appear to be filled to the same level independent of container volume variations. These type fillers are also compatible with most free flowing products and can tolerate small particulates.

Positive displacement filler

The name derives from the type of pump used in this type filler. A positive displacement pump moves product with gears or lobes meshing with tight tolerances. The volume of product moved is a function of the number of pump shaft rotations. This style of pump can handle thicker product but abrasive particulates will shorten pump life.

Piston filler

Piston fillers work like a physician’s syringe. The piston pulls product into the cylinder and then pushes it into the container. Two Check valves direct the flow of product. One check valve opens when the piston pulls product into the cylinder and then closes when product is pushed out of the cylinder. The second check valve closes on the intake stroke and opens on the output stroke. The piston is slower than other types of fillers but it handles products that other fillers cannot.

Accutek Sales Engineer’s experience will help you sort through your requirements to identify the proper filler for your application. Accutek Packaging Equipment works with you to meet your packaging needs, no matter what your budgetary constraints might be. Call for assistance in choosing the filler you need.