Accutek Packaging is the leading supplier of packaging machines in the world. With hundreds of machine designs, we meet our customer’s needs for complete inline filling systems. We have been serving the packaging industry for over thirty years, acquiring a tremendous amount of expertise in packaging machine design and manufacture.

The first small packaging machine produced by Accutek was a timed flow liquid filler. Thirty years ago, packaging machines were not nearly as flexible as they are today. Timing and control were accomplished mechanically and with a few relays. Accutek was an industry leader in the transition to programmable electronics operating pneumatic actuators. Current technology is again evolving from pneumatic to servo or stepper motor actuators. Once again, Accutek is at the forefront of this evolution. Our goal is to be a leader in providing our customers with the fastest and most accurate packaging machines.

Packaging Machine Line Design and Development

Accutek sales engineers are packaging experts, eager to assist you in the design of a turnkey packaging Machine line. Our company offers simple semi-automated machines for startup companies, as well as fully automated complete packaging lines for mature companies.

An essential part of the design process is developing the container handling hardware. We routinely adapt our production lines to handle all types of plastic, metal, and glass containers.

You supply the containers, caps, labels, cases, and product. The Accutek team will produce a packaging solution that will meet your requirements. The sequence of operations begins with container preparation. This involves organizing and placing the containers on a conveyor for transport through a cleaning station. The cleaned containers then enter a filler.

Choosing a Filling & Packaging Machine

The product characteristics, anything from water to peanut butter, determine the technology best suited for our customers. Accutek’s timed flow volumetric filling machines are best suited for filling liquids with low to medium viscosity. These fillers are highly accurate, very sanitary, and have options for filling molten products. They can be used to fill light foamy products as well.

Accutek’s overflow filling machines are also suited for filling low to medium viscosity liquids. These fillers are great at filling foamy products at higher speeds. Examples of products suited for overflow filling machines are non-carbonated aqueous beverages, sauces, syrups, light gels, shampoos, water, fruit juice, wine, tea, and foamy cleansers or chemicals.

Our piston filling machines are ideal for filling sauces, pastes, creams, lotions, gels, peanut butter, and products that have large particulates or chunks. With options for filling molten products, this type of filler can handle lip balm, honey, and heavy syrups. Cleaning is a simple process, as no tools are required. All our piston filling machines are made with heavy-duty stainless steel frames and all contact parts made with food-grade materials.

Accutek’s positive displacement pump filling machines are suited for filling viscous products, or they can be used to fill thin products as well. They are ideal for filling pastes, creams, lotions, and gels, in large volumes and at higher speeds than otherwise achieved with a piston filler. Positive displacement fillers can also process molten products such as lip balm, honey, and heavy syrups. Accutek Net Weight filling machines bulk-fill liquid or semi-liquid products into drums or buckets. Easy to use and durable stainless steel construction make each net weight filler a long-lasting investment.

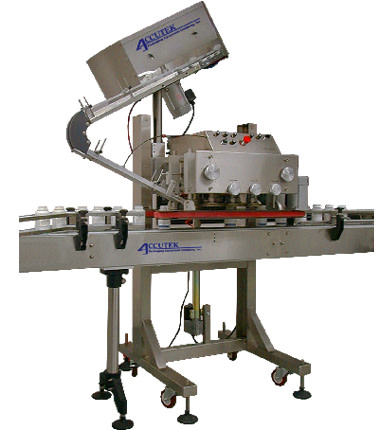

The next packaging machine in the process secures a closure (cap) on a container. Caps are bulk loaded into a hopper where they are oriented and organized to be picked up by a container just before being screwed on, pressed on, snapped on, or stomped.

An attractive label is needed to get your product chosen over competing products on the same shelf. Accutek manufactures a wide variety of labeling equipment to automatically place and secure most label types onto a wide assortment of container types. Accutek labeling machines utilize the latest technologies to achieve the highest speeds and most accurately labeled bottles on the market. Three different styles of labeling systems are available: pressure sensitive labelers, hot melt glue labelers, and sleeve labelers. Labelers can range from high-speed sleeve labeling systems down to single head bench top labelers for low-speed labeling.

Packaging Mahcine Line Support Equipment

Filled, capped, and labeled containers are ready to be packed in cases and palletized for storage or shipment to a retailer. Accutek has case formers, packers, and tapers that can be ordered with the rest of your Accutek’s packaging machine.

We supply our customers with a complete packaging line, installation, and service with a single purchase order. Accutek liquid packing machines have been used for juice, water, beverage, dairy, brewing, distilled spirits, wine, pharmaceutical, nutritional, industrial cleaners, household products, and chemical industries. Accutek thoroughly tests every component and the integration of the complete packaging line. We offer factory acceptance testing to our customers, and we carefully crate and ship your order from our factory in Vista, California.)