Labeling Machine: A Critical Component in Modern Packaging Operations

Labeling machines play a central role in product presentation, compliance, and traceability across nearly every manufacturing sector. From food and beverage to pharmaceuticals and cosmetics, accurate and consistent labeling ensures products meet regulatory standards while maintaining brand integrity on the shelf.

As packaging operations scale and diversify, labeling equipment must deliver reliability, flexibility, and integration efficiency. Modern labeling machines are no longer standalone tools—they are engineered systems designed to support production accuracy, throughput, and long-term operational growth.

The Role of Labeling Machines in Today’s Packaging Lines

Labeling machines apply printed information—such as branding, ingredients, barcodes, and compliance data—directly onto containers. Depending on the application, this can include:

-

Front-and-back labeling

-

Wrap-around labeling

-

Top or bottom labeling

-

Tamper-evident or full-body applications

In automated environments, labeling machines must synchronize seamlessly with filling, capping, and inspection equipment to maintain consistent line performance.

Types of Labeling Machines Used in Manufacturing

Different packaging formats require different labeling technologies. The most common configurations include:

| Labeling Type | Typical Application | Key Advantage |

|---|---|---|

| Pressure-sensitive labelers | Bottles, jars, containers | High accuracy and versatility |

| Wrap-around labelers | Cylindrical containers | Uniform label placement |

| Front-and-back labelers | Flat or square containers | Precise multi-panel labeling |

| Top & bottom labelers | Boxes, pouches, trays | Product identification and tracking |

| Sleeve labelers | Beverage and cosmetic containers | Full-body branding and tamper evidence |

Key Factors That Define a High-Performance Labeling Machine

Modern labeling systems must meet more than just speed requirements. Performance is defined by consistency, adaptability, and reliability.

Core performance considerations include:

-

Label placement accuracy across varying container sizes

-

Changeover efficiency for multi-SKU production

-

Compatibility with different label materials

-

Consistent adhesion and alignment

-

Integration with upstream and downstream equipment

Machines built with modular designs and servo-driven controls typically outperform rigid, single-use systems.

How Labeling Machines Support Production Efficiency

An effective labeling machine contributes to overall line efficiency in several ways:

-

Reduces manual handling and labeling errors

-

Maintains consistent throughput across shifts

-

Minimizes downtime during changeovers

-

Supports traceability and compliance requirements

When properly integrated, labeling equipment becomes a stabilizing element in the production process rather than a bottleneck.

Common Applications Across Industries

| Industry | Labeling Requirements | Operational Benefit |

|---|---|---|

| Food & Beverage | Ingredient, nutrition, barcode labels | Regulatory compliance |

| Pharmaceuticals | Lot, batch, and dosage information | Traceability and safety |

| Cosmetics | Brand presentation and aesthetics | Shelf appeal |

| Chemicals | Hazard and handling labels | Safety and compliance |

| Consumer Goods | High-speed labeling | Production efficiency |

Why Manufacturers Invest in Advanced Labeling Systems

Manufacturers increasingly prioritize labeling solutions that can evolve with production demands. Modern labeling machines are designed to support:

- Scalable production volumes

- Faster product changeovers

- Integration with inspection and vision systems

- Long-term reliability in high-output environments

These capabilities help manufacturers maintain consistency while adapting to market and regulatory changes.

Selecting the Right Labeling Machine

-

Choose systems that align with current and future production needs

-

Prioritize accuracy and repeatability over raw speed alone

-

Ensure compatibility with existing packaging equipment

-

Select platforms that support scalability and long-term growth

-

Work with manufacturers that offer engineering support and customization

A well-designed labeling machine is not just a piece of equipment—it’s a foundational component of an efficient, compliant, and scalable packaging operation.

Showing all 21 results

Labelette SPS-104 with Thermal Printer

The Labelette SPS-104 Tabletop Labeler with Thermal Printer is a compact and efficient labeling machine designed for round containers.

Labelette SPS-104 with Thermal Printer

The Labelette SPS-104 Tabletop Labeler with Thermal Printer is a compact and efficient labeling machine designed for round containers.

Labelette HG

The labeling machine Labelette HG Labeler will index labels, transfer adhesive, and accurately apply a plain paper label to a container.

Labelette HG

The labeling machine Labelette HG Labeler will index labels, transfer adhesive, and accurately apply a plain paper label to a container.

Labelette SG

The labeling machine Labelette SG Labeler will separate the label from a stack, feed the label, transfer adhesive, and accurately apply the paper label to the container.

Labelette SG

The labeling machine Labelette SG Labeler will separate the label from a stack, feed the label, transfer adhesive, and accurately apply the paper label to the container.

Labelette FS

Labelette’s F-Style glue labeling machines are designed to eliminate the problems associated with labeling canisters and rectangular products.

Labelette FS

Labelette’s F-Style glue labeling machines are designed to eliminate the problems associated with labeling canisters and rectangular products.

Labelette SPS-104

Labelette’s (Semi-Automatic Pressure Sensitive) SPS-104 is an economical and efficient labeling machine for round containers. The unit is manufactured from Stainless Steel and anodized aluminum creating a durable but portable machine.

Labelette SPS-104

Labelette’s (Semi-Automatic Pressure Sensitive) SPS-104 is an economical and efficient labeling machine for round containers. The unit is manufactured from Stainless Steel and anodized aluminum creating a durable but portable machine.

SPS-106 Labeler – Top-down Labeler

Labelette’s SPS-106 Table Top, Top-down Labeler is an economical and efficient countertop labeling machine for top side labeling of rectangular labels.

SPS-106 Labeler – Top-down Labeler

Labelette’s SPS-106 Table Top, Top-down Labeler is an economical and efficient countertop labeling machine for top side labeling of rectangular labels.

APS-004

The labeling machine APS-004 Adjustable Label Head is economical, self-contained, easy to operate, and fully height and angle adjustable. It is capable of labeling at any angle within a 90° range and can easily convert from a side labeler into a top labeler.

APS-004

The labeling machine APS-004 Adjustable Label Head is economical, self-contained, easy to operate, and fully height and angle adjustable. It is capable of labeling at any angle within a 90° range and can easily convert from a side labeler into a top labeler.

APS-104

The labeling machine APS-104 Top Labeler is economical, self-contained and easy to operate. This automatic labeling system comes equipped with a height adjustable 4 ft. variable speed belted conveyor.

APS-104

The labeling machine APS-104 Top Labeler is economical, self-contained and easy to operate. This automatic labeling system comes equipped with a height adjustable 4 ft. variable speed belted conveyor.

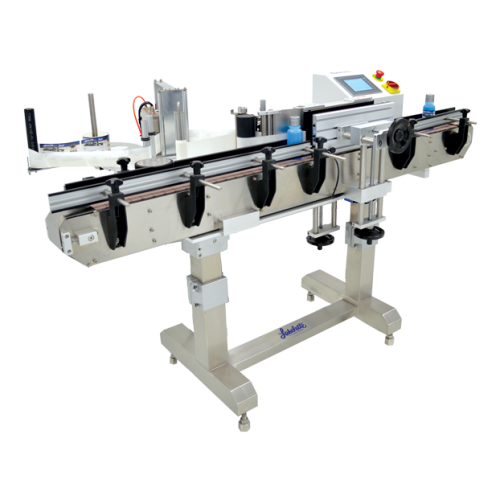

APS 106

The labeling machine APS-106 is economical, self-contained and easy to operate. This automatic labeling system comes equipped with a 6 ft. variable speed conveyor.

APS 106

The labeling machine APS-106 is economical, self-contained and easy to operate. This automatic labeling system comes equipped with a 6 ft. variable speed conveyor.

106 Fabric Belt Labeler

The labeling machine APS 106 Fabric Belt Labeler is a revolutionary automatic pressure sensitive labeler designed for efficient label application onto containers.

106 Fabric Belt Labeler

The labeling machine APS 106 Fabric Belt Labeler is a revolutionary automatic pressure sensitive labeler designed for efficient label application onto containers.

APS 106 TA Labeler

Labeling machine 106 TA is a pressure-sensitive labeler which is designed to wrap tapered containers.

APS 106 TA Labeler

Labeling machine 106 TA is a pressure-sensitive labeler which is designed to wrap tapered containers.

APS 108

The APS-108 is economical, self contained and easy to operate. This automatic labeling machine comes equipped with a 6 ft. variable speed conveyor.

APS 108

The APS-108 is economical, self contained and easy to operate. This automatic labeling machine comes equipped with a 6 ft. variable speed conveyor.

APS-134

The labeling machine APS-134 is an easy to operate Automatic Horizontal Wrap Labeler. The APS-134 is designed to label unwieldy round containers horizontally oriented with a full or partial wrap label such as pens, lip sticks, test tubes/ampules and other cylindrical containers.

APS-134

The labeling machine APS-134 is an easy to operate Automatic Horizontal Wrap Labeler. The APS-134 is designed to label unwieldy round containers horizontally oriented with a full or partial wrap label such as pens, lip sticks, test tubes/ampules and other cylindrical containers.

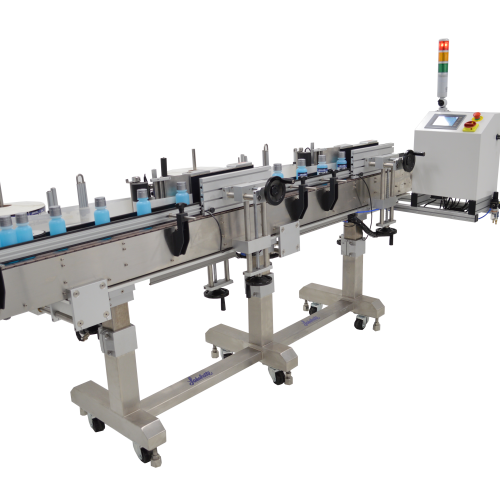

APS 206 Labeler

The APS-206 Labeler is economical, self-contained and easy to operate. This automatic labeling machine system comes equipped with a 10 ft. variable speed conveyor. Additional features include, stepper motor driven label dispenser, take up reel and label tampers.

APS 206 Labeler

The APS-206 Labeler is economical, self-contained and easy to operate. This automatic labeling machine system comes equipped with a 10 ft. variable speed conveyor. Additional features include, stepper motor driven label dispenser, take up reel and label tampers.

APS 208

The labeling machine APS-208 is economical, self contained and easy to operate. This automatic labeling system comes equipped with a 10 ft. variable speed conveyor.

APS 208

The labeling machine APS-208 is economical, self contained and easy to operate. This automatic labeling system comes equipped with a 10 ft. variable speed conveyor.

APS 218

The labeling machine APS-218 is economical, self contained and easy to operate. This automatic labeling system comes equipped with a 10 ft. variable speed conveyor.

APS 218

The labeling machine APS-218 is economical, self contained and easy to operate. This automatic labeling system comes equipped with a 10 ft. variable speed conveyor.

APS 228

Like the labeling machine APS-218 , the APS-228 is economical, self contained and easy to operate. This automatic labeling system comes equipped with a 10 ft. variable speed conveyor.

APS 228

Like the labeling machine APS-218 , the APS-228 is economical, self contained and easy to operate. This automatic labeling system comes equipped with a 10 ft. variable speed conveyor.

APS-236 Labeler

The labeling machine APS-236 is a specialized dual head labeler designed specifically for top and bottom label applications.

APS-236 Labeler

The labeling machine APS-236 is a specialized dual head labeler designed specifically for top and bottom label applications.

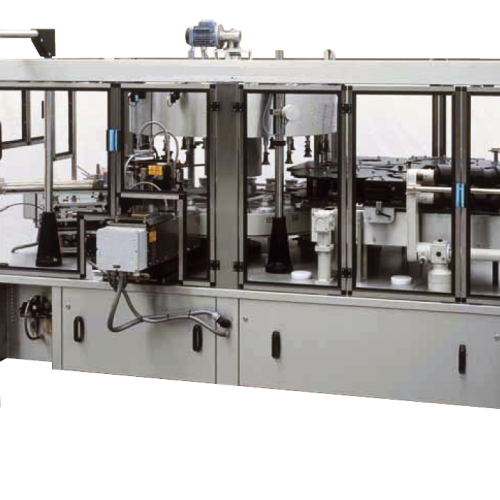

RL-HG 540

The RL-HG 540 labeling machine is the perfect machine for any high volume Hot Melt Glue labeling projects that requires the application of paper or plastic label to a cylindrical container.

RL-HG 540

The RL-HG 540 labeling machine is the perfect machine for any high volume Hot Melt Glue labeling projects that requires the application of paper or plastic label to a cylindrical container.

RL-540

The labeling machine RL-540 Rotary systems are designed with the needs of the contract packaging and demanding end user in mind.

RL-540

The labeling machine RL-540 Rotary systems are designed with the needs of the contract packaging and demanding end user in mind.

Frequently Asked Questions (FAQ)

What is a labeling machine used for?

A labeling machine applies printed labels to containers such as bottles, jars, boxes, or pouches. These labels may include branding, ingredients, barcodes, safety information, or regulatory data required for product identification and compliance.

What industries commonly use labeling machines?

Labeling machines are widely used across industries including food and beverage, pharmaceuticals, cosmetics, chemicals, nutraceuticals, and consumer packaged goods. Each industry may require different label types, materials, and accuracy levels.

What types of labeling machines are available?

Common types include:

-

Pressure-sensitive labelers

-

Wrap-around labeling machines

-

Front-and-back labelers

-

Top and bottom labelers

-

Sleeve labeling systems

Each type is designed for specific container shapes and production requirements.

How do I choose the right labeling machine for my production line?

The right labeling machine depends on several factors:

-

Container shape and material

-

Label size and application style

-

Production speed requirements

-

Integration with existing equipment

-

Future scalability needs

Evaluating these factors ensures long-term efficiency and compatibility.

Can labeling machines handle multiple product sizes?

Yes. Many modern labeling systems are designed with adjustable components and quick-change features that allow manufacturers to switch between product sizes with minimal downtime.

Are labeling machines compatible with automated packaging lines?

Most industrial labeling machines are designed to integrate seamlessly with filling, capping, and inspection systems, allowing for fully automated packaging lines.

What maintenance is required for labeling machines?

Routine maintenance typically includes:

-

Cleaning label sensors and applicators

-

Inspecting belts and rollers

-

Verifying alignment and calibration

-

Replacing wear components as needed

Regular maintenance helps ensure consistent labeling accuracy and prolongs machine life.

Why is labeling accuracy important?

Accurate labeling ensures regulatory compliance, protects brand integrity, and prevents costly product recalls. It also improves consumer trust and supports traceability throughout the supply chain.